AGV SOLUTIONS

Driverless transport systems

AGV Technology & Strategy for production and logistics

Many companies are faced with considerations and decisions to introduce AGV systems in their production and/or logistics. The range of different applications from simple track-guided vehicles to complex, fully integrated systems is unmanageable for non professionals. The half-life of the technology is less than 2.5 years.

Ever newer, better technologies are leading to sharply increasing quantities and new possible applications for driverless transport systems (DTS).

Our Services

Contact us – we will help you immediately!

Conception and Strategy

The question of what should be achieved in the medium and long term with the use of AGV technology determines the individual solution for the company …

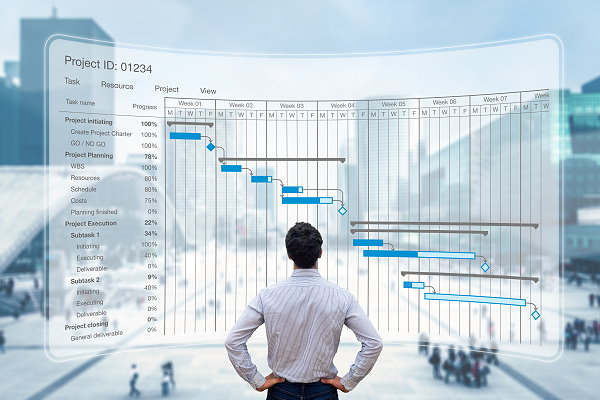

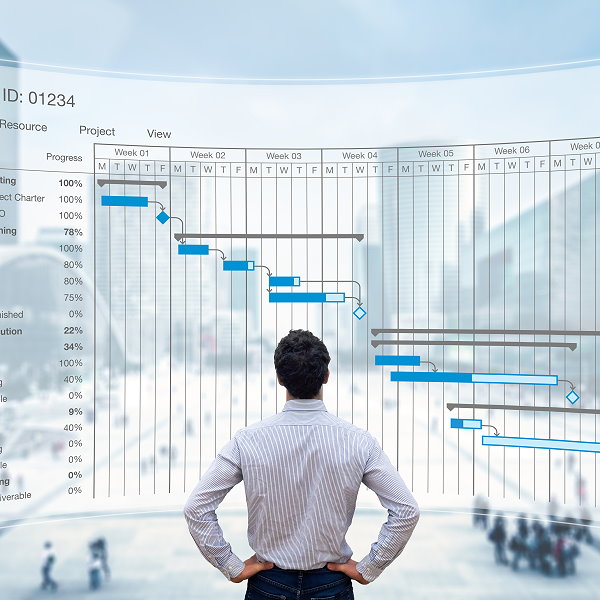

Planning & System Design

The type of vehicle is determined by the load, the topology, the pick-up/handover points, the operating and usage times and much more. The integration of the system …

Tender- and awarding-phase

Conceptually meaningful, realistic and complete documents are the basis of a successful tender-process. The specification also includes all conditions of use and operation …

Implementation support

After the assignment, the focus is on technical and organizational details. The experienced project manager is often on the supplier’s side, and we often find a rookie on the customer’s side who is responsible for his first …

Installation

On the construction site during commissioning, it becomes apparent whether the scope of delivery and services, the tasks and roles, and the responsibilities were fully coordinated. Is it really clear who …

Certification and handovers

What use is the best planned site acceptance test procedure if it cannot be implemented. If material, interfaces or environmental requirements are not available. If production …

Services and support

Do you want to reach someone, or are you actually getting the support you need?

You often turn to the manufacturer because you don’t know the alternatives. Experience shows …

Optimization of existing system

Unfortunately, a (too) large number of AGV systems in operation does not meet the expectations and/or the requirements of the operators. The reasons …

AGV Technology & Strategy for Production and Logistics

AGV-Solutions offers you over 30 years of experience in logistics, production and maintenance. Our strength lies in project management around factory planning and conveyor technology.

We are happy to support and advise you on the AGV implementation with our specialist knowledge of driverless transport systems.

Conception and Strategy

The question of what should be achieved in the medium and long term with the use of AGV technology determines the individual solution for the company.

Often underestimated at the beginning, you can tell at the latest when you expand or repeat a project at another location, whether the thinking was strategic and long-term.

The constant change in the supplier market, the frequent company takeovers, the rapid changes in technology, and many other influencing factors show at the latest in the operation and maintenance phase whether the selected system/supplier decision is viable and cost-effective in the long term.

Planning & System Design

The type of vehicle is determined by the load, the topology, the pick-up/handover points, the operating and usage times and much more.

The integration of the system, the requirements for availability and operating times, the integration and communication requirements are essential influencing factors for the SYSTEM.

If you combine the vehicle type with system requirements and the environmental conditions (e.g. including the layout), an initial concept can be created in close cooperation as a planning and discussion basis.

Tender- and awarding-phase

Conceptually meaningful, realistic and complete documents are the basis of a successful tender-process. The specification also includes all conditions of use and operation as well as future expectations and requirements of the customer. An expandability or later adjustment of the system should be considered from the beginning.

With our good knowledge of the market and providers, we ensure that negotiable and suitable offers are available for the technical coordination talks. Together we create the conditions for a successful and economical assignment.

Implementation support

After the assignment, the focus is on technical and organizational details. The experienced project manager is often on the supplier’s side, and we often find a rookie on the customer’s side who is responsible for his first AGV project. He is often confronted with a large number of questions and requirements that are not easy to answer and often have far-reaching consequences.

It is in the nature of things that interests differ. It pays off if you provide your employees with an experienced, “neutral” AGV expert to ensure the long-term success of the project.

Installation

On the construction site during commissioning, it becomes apparent whether the scope of delivery and services, the tasks and roles, and the responsibilities were fully coordinated. Is it really clear who is responsible for which topics and what needs to be delivered?

Frequently it is not just a question of getting an AGV system to “run” but rather of implementing an overall process. In the case of integration issues, when different partners with individual interests are involved, it becomes clear whether the responsibilities and the scope of delivery and services are regulated.

Experienced project management with a technical AGV background knows which details are important and regulates responsibilities in good time or implements processes and tests so that the interaction of the systems can also be put into operation successfully.

Certification and handovers

What use is the best planned site acceptance test procedure if it cannot be implemented. If material, interfaces or environmental requirements are not available. If production or upstream/downstream logistics processes do not generate any utilization for the commissioning of the AGV system?

The target/overall process may have been perfectly described in the tender-phase, but unfortunately it does not match reality. Often upstream or downstream areas and/or facilities are not installed, or not-ready-for-production, or simply unavailable. The AGVS supplier cannot and does not have to take responsibility for this.

Realistic availability tests and acceptance criteria should nevertheless allow you to have a timely and complete certification, and thus take it over to the operator. At this point, at the latest, it becomes clear whether the project has “thought far enough”.

We are experienced enough to identify such setups (possibly as backups) at the beginning of the project, to define them and to agree them with the commissioning.

Services and support

Do you want to reach someone, or are you actually getting the support you need?

You often turn to the manufacturer because you don’t know the alternatives. Experience shows that manufacturer-independent service companies can also support proprietary systems successfully and cost-effectively.

A well-organized project takes lifecycle costs into account from the start. Recently available smart-contracting contracts allow performance-dependent remuneration …. but only if done correctly.

We have experience, know the market and can support you with such questions.

Optimization of existing systems

Unfortunately, a (too) large number of AGV systems in operation does not meet the expectations and/or the requirements of the operators.

The reasons for this are wide-ranging – requirements or environmental conditions have often changed, sometimes the planning was not based on needs. Adjustments are unavoidable in order to be able to operate the installed AGV system profitably.

We analyze existing systems, find weak points and develop suggestions for optimizing your installed AGV system.

If there are differences of interest between the operator and the supplier, we can provide neutral coordination or mediation.